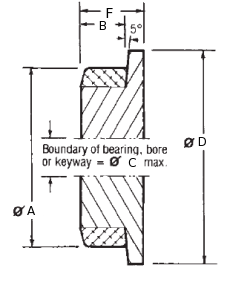

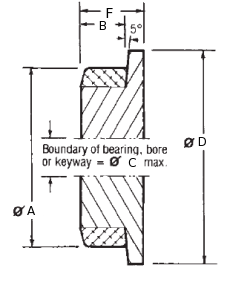

Standard wheel features flanges with a 5º angle and a ´flat tread´ (ie tread parallel

to the wheel axis) for running on flat top rail. Polyurethane is resilient, durable

material, resistant to abrasion and to many common chemicals. Polyurethane

tyred wheels are capable of carrying heavy loads and of transmitting driving

forces.

MATERIAL: Wheel Centre - Steel to BS970: Part 1: 1983: 080M40

Tyre - Polyester Based Polymer of 92º ± 3º Shore A Hardness

OPERATING TEMPERATURE RANGE:

-20ºC to +60ºC (115ºC for limited use)

PLEASE SPECIFY IF OPERATING IN HIGH HUMIDITY.

Anti-hydrolysis polyurethane is recommended for use in an operating

environment of high humidity.

Polyurethane to the above hardness used on these wheels is Vulkollan, a

high quality material that provides superior performance in most

applications.

Should the mechanical properties of Vulkollan be inappropriate for the

application, alternative grades of Polyurethane can be produced to meet

the requirements. Polyurethane can be bonded onto most metal centres

including aluminium, titanium, stainless steel and various ferrous and

non-ferrous alloys.

The ´Maximum Load Rating´ given for each wheel assumes the full tread width is in contact with the rail. In practice full contact with the rail

across the tread width is rarely achieved due to:-

a) Flange to rail clearance

b) Wheel Overhang

c) Rail Corner Radii

For calculation of the ´Maximum Allowable Load´ see

´Design Data´ para. 5.1.

In addition the ´Maximum Load Rating´ given for each wheel is for operation under ideal conditions.

Load factors must be applied according to the anticipated working conditions - see

´Design Data´ para. 4.1.

Alternative Bore/Bearing diameters and alternative bearing types (i.e) bronze brushes, self lubricating brushes,

etc.) are available to order -

see

´Design Data´ para. 6.0. |