Wheels

Airmovers

Brauer Info.

|

||||||||||||||||

Click on Product Group code to view Bearing options and full Part Numbers. |

<< Back |

|||||||||||||||

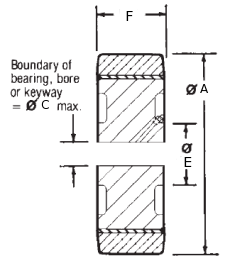

| Product Group | Tread Ø mm(A) | Tread Width mm(B) | Max Bore mm(C) | Flange Ø mm(D) | Hub Ø mm(E) | Hub Width mm(F) | Overall Width mm(G) | Load Kg | Weight Kg | |||||||

| PH250/75 | 250 | 75 | 75 | - | 100 | - | - | 2000 | 20 | |||||||

| PH250/125 | 250 | 125 | 75 | - | 100 | - | - | 3400 | 33 | |||||||

| PH300/75 | 300 | 75 | 75 | - | 100 | - | - | 2550 | 28 | |||||||

| PH350/100 | 350 | 100 | 125 | - | 175 | 90 | 107.5 | 3600 | 40 | |||||||

| PH380/75 | 380 | 75 | 125 | - | 175 | 90 | - | 2700 | 36 | |||||||

| PH380/100 | 380 | 100 | 125 | - | 175 | 90 | 107.5 | 3600 | 45 | |||||||

| PH380/125 | 380 | 125 | 125 | - | 175 | 90 | 132.5 | 4500 | 53 | |||||||

| PH400/100 | 400 | 100 | 125 | - | 175 | - | - | 3800 | 65 | |||||||

| PH400/125 | 400 | 125 | 125 | - | 175 | - | - | 4800 | 80 | |||||||

| PH460/75 | 460 | 75 | 125 | - | 175 | 90 | - | 3200 | 45 | |||||||

| PH460/100 | 460 | 100 | 125 | - | 175 | 90 | 107.5 | 4200 | 52 | |||||||

| PH500/75 | 500 | 75 | 125 | - | 175 | 100 | - | 3600 | 65 | |||||||

| PH500/100 | 500 | 100 | 125 | - | 175 | - | - | 4800 | 70 | |||||||

Unlike the less expensive polyurethane tyred wheels shown

´Polyurethane Tyre´

which have the tyre bonded directly to the wheel centre, ´Press-on Band´

wheels have the tyre bonded to a thin steel band which is press-fitted to the

wheel centre allowing the tyre to be replaced when worn. |

||||||||||||||||

Best viewed in Firefox, Mozilla, Opera or Internet Explorer 7. IE6 and below will not work correctly on some pages.