Wheels

Airmovers

Brauer Info.

|

||||||||||||||||

Click on Product Group code to view Bearing options and full Part Numbers. |

<< Back |

|||||||||||||||

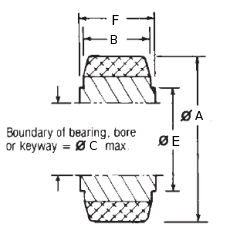

| Product Group | Tread Ø mm(A) | Tread Width mm(B) | Max Bore mm(C) | Flange Ø mm(D) | Hub Ø mm(E) | Hub Width mm(F) | Overall Width mm(G) | Load Kg | Weight Kg | |||||||

| H75/35 | 75 | 35 | 40 | - | - | - | - | 300 | 0.5 | |||||||

| H85/75 | 85 | 75 | 35 | - | - | - | - | 700 | 0.6 | |||||||

| H100/40 | 100 | 40 | 45 | - | 63 | 45 | - | 450 | 1.5 | |||||||

| H100/100 | 100 | 100 | 50 | - | - | - | - | 1100 | 5 | |||||||

| H125/30 | 125 | 30 | 40 | - | 58 | 35 | - | 400 | 1.5 | |||||||

| H125/45 | 125 | 45 | 45 | - | 60 | 50 | - | 600 | 2 | |||||||

| H150/35 | 150 | 35 | 40 | - | 58 | 40 | - | 600 | 2 | |||||||

| H150/50 | 150 | 50 | 50 | - | 63 | 55 | - | 900 | 3 | |||||||

| H150/150 | 150 | 150 | 75 | - | - | - | - | 2300 | 7 | |||||||

| H200/40 | 200 | 40 | 50 | - | 65 | 50 | - | 900 | 4 | |||||||

| H200/60 | 200 | 60 | 60 | - | 83 | 70 | - | 1400 | 7 | |||||||

| H200/75 | 200 | 75 | 60 | - | 83 | - | - | 1750 | 14.4 | |||||||

| H250/45 | 250 | 45 | 60 | - | 85 | 55 | - | 1300 | 7 | |||||||

| H250/70 | 250 | 70 | 75 | - | 102 | 80 | - | 2000 | 12 | |||||||

| H250/97.5 | 250 | 97.5 | 75 | - | 100 | 97.5 | - | 2700 | 19.5 | |||||||

| H300/50 | 300 | 50 | 60 | - | 86 | 60 | - | 1500 | 10 | |||||||

| H300/75 | 300 | 75 | 75 | - | 100 | 85 | - | 2300 | 16 | |||||||

| H300/100 | 300 | 100 | 75 | - | 100 | - | - | 3100 | 18 | |||||||

| H350/100 | 350 | 100 | 100 | - | 165 | - | - | 3600 | 52 | |||||||

| H400/100 | 400 | 100 | 100 | - | 165 | 110 | - | 4200 | 39.5 | |||||||

| H400/125 | 400 | 125 | 100 | - | 165 | - | - | 5200 | 48.5 | |||||||

| H460/75 | 460 | 75 | 100 | - | 150 | 90 | - | 3500 | 40 | |||||||

Polyurethane is resilient, durable material, resistant to abrasion and to many

common chemicals. Polyurethane tyred wheels are capable of carrying heavy

loads and of transmitting driving forces. |

||||||||||||||||

Best viewed in Firefox, Mozilla, Opera or Internet Explorer 7. IE6 and below will not work correctly on some pages.