Wheels

Airmovers

Brauer Info.

Brauer Airmovers: |

|

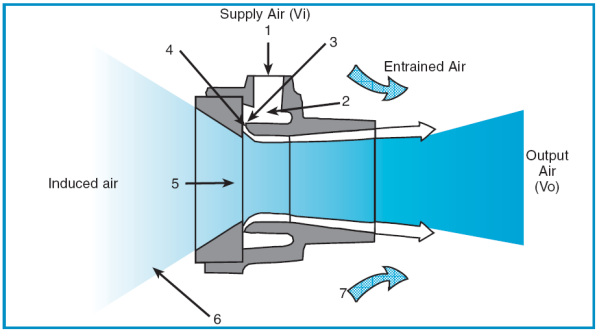

If you are looking to convey light materials, extract fumes, smoke or air, or simply cool down a hot area of a product quickly then airmovers provide a simple, cost effective means of achieving your aim. Using the energy from a small volume of compressed air (supplied from a standard compressor) an airmover amplifies surrounding air to high volume, low pressure output airflow using the coanda effect. Airmovers are extremely quiet and efficient and can amplify compressed air input up to 100 times allowing increased airflow while substantially reducing compressed air consumption. How Airmovers Work An airmover is an air flow amplifier - it uses the energy from a small volume of compressed air (from the normal shop supply) to produce a high velocity, high volume, low pressure output airflow.

Vi = Volume of supply air (free air at atmospheric pressure) Compressed air flows from the supply inlet (1) into an annular chamber (2). |

|

Best viewed in Firefox, Mozilla, Opera or Internet Explorer 7. IE6 and below will not work correctly on some pages.